PRODUCT

CNC pipe thread lathe used in petroleum industry

The application of CNC pipe thread lathes in the petroleum industry: drilling pipe thread processing, oil well casing processing, tubing processing, drilling tool processing, etc.

CNC pipe thread lathes are widely used in the petroleum industry. Here are some application examples:

1. Drilling pipe thread processing: CNC pipe thread lathe can be used to process various types of drilling pipe threads. These threads connect drill pipe, casing and other drilling equipment to ensure the smooth progress of drilling operations.

2. Oil well casing processing: In the process of oil exploitation, oil well casing plays the role of isolating oil layers and formations. The CNC pipe thread lathe can be used to process the thread and connection port of the casing to ensure that the casing can be installed and connected safely.

3. Oil pipe processing: The oil pipe is the pipeline that transports oil from the oil well to the ground. The CNC pipe thread lathe can be used to process the thread and connection of the oil pipe to ensure the sealing and reliability of the pipe.

4. Drilling tool processing: In the process of oil exploration and exploitation, various types of drilling tools are used. The CNC pipe thread lathe can be used to process the thread and connection port of the drilling tool to ensure that the drilling tool can be firmly connected and operated.

The CNC pipe thread lathe improves the processing efficiency and product quality through the automatic processing process and precise control, and provides important support for the production of the petroleum industry. At the same time, it also brings higher safety and reliability to the development of the petroleum industry.

Product Specifications:

| Project | Content | Unit | QK1322 |

| Processing range | Maximum turning diameter of bed | mm | Φ630 |

| Maximum turning diameter on the skateboard | mm | Φ330 | |

| Maximum processing length | mm | 1500 | |

| Maximum machining diameter | mm | Φ630 | |

| Maximum bar diameter | mm | Φ330 | |

|

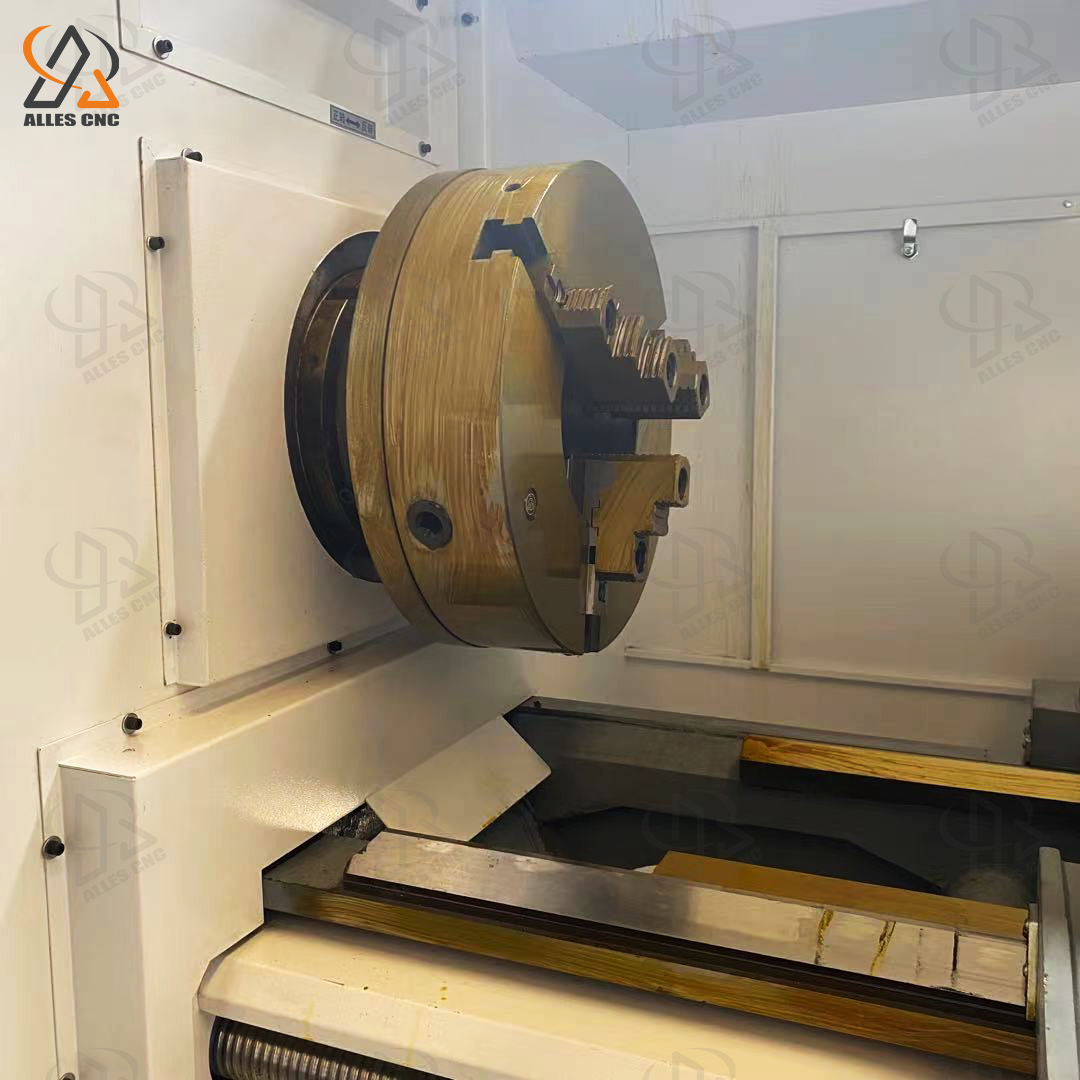

Spindle |

Chuck | / | Front and rear 500 four claws |

| Spindle head form | / | D11 | |

| Spindle through hole diameter | mm | Φ220 | |

| Spindle bore taper | / | 1:20 | |

| Spindle series | / | Manual second gear | |

| Spindle speed range | r/min | 25-89/108-382 | |

|

feed |

X/Z axis travel | mm | 350/1500 |

| X/Z rapid traverse speed | m/min | 4/6 | |

|

Tool |

Tool holder form | / | Tool holder |

| Number of stations | / | 4 | |

| Tool Specifications: Turning/Boring | mm | 32/40 | |

|

tailstock |

Sleeve diameter/stroke | mm | Φ100/250 |

| Sleeve inner hole taper | / | MT6 | |

| Sleeve drive form | / | manual | |

| Tailstock body movement form | / | manual | |

| motor | Spindle motor power | Kw | 11 |

| Spindle motor torque | NM | 48 | |

| X/Z motor power | Kw | 1.5/2.3 | |

| X/Z motor torque | NM | 10/15 | |

| Others | Machine weight | kg | 4200 |

| Machine tool dimensions: length × width × height | mm | 3750/1830/1900 |