PRODUCT

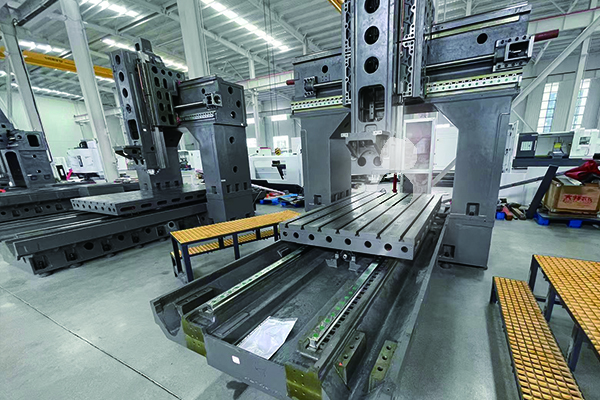

ALGMC3020 Large CNC Gantry Milling Machine for Aerospace and Automotive Parts

The ALGM3020 gantry milling machine is a high-precision, high-rigidity CNC gantry milling machine designed for machining medium-to-large and complex parts. Thanks to its advanced structural design, high-precision control system, and high load capacity, the ALGM3020 is widely used in mold manufacturing, the aerospace industry, mechanical parts processing, and the automotive industry.

The ALGM3020 gantry milling machine is a high-precision, high-rigidity CNC gantry milling machine designed for machining medium-to-large and complex parts. Thanks to its advanced structural design, high-precision control system, and high load capacity, the ALGM3020 is widely used in mold manufacturing, the aerospace industry, mechanical parts processing, and the automotive industry.

I. Main Advantages

High Rigidity and Stability:The heavy-duty cast iron bed and double-column gantry structure ensure machine stability during high cutting loads and long-term continuous machining.

High-Precision Machining Capability:Equipped with high-precision ball screws and linear guides, the ALGM3020 achieves micrometer positioning accuracy, ensuring precise machining of complex and large parts.

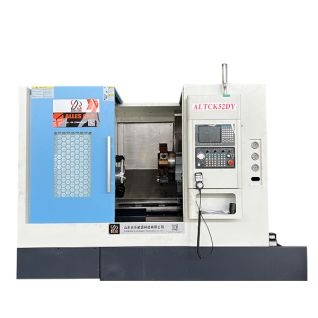

Automation and Intelligent Operation:The integrated CNC control system enables automated machining, program optimization, and continuous multi-step machining. A centralized lubrication system ensures stable operation of key components and reduces maintenance costs.

High Load Capacity:The large worktable capacity allows for handling heavy or oversized workpieces, meeting the demands of the automotive, aerospace, and machine-building industries.

Durability and Reliability:High-quality materials and precise machining processes extend the machine's lifespan. Heat treatment and stress relief processes ensure efficient and stable long-term operation.

II. Application Industries

Due to its high precision and large-scale machining capacity, the ALGM3020 is used in multiple high-end industries:

Mold Manufacturing: Machining medium-to-large injection molds, stamping molds, and die-casting molds.

Aerospace: Machining of engine parts, structural components, and large aircraft structures.

Machinery Manufacturing: Large machine tool parts, engineering components, and precision mechanical structures.

Automotive: Machining of engine blocks, transmission housings, body structures, and chassis parts.

Energy and Equipment: Wind turbine parts, shipbuilding parts, and large machinery components.

III. Main Features

Double-column gantry structure:Provides extremely high load capacity and stability, ideal for large parts and heavy-duty cuts.

High-precision guide system:Three-axis linear guides ensure smooth motion and long-term stable precision.

High-rigidity spindle system:Allows high-speed cutting and heavy-duty machining, ensuring the surface quality of the parts.

Automatic centralized lubrication system:Reduces wear on key components and extends the machine's lifespan and stability.

Versatile Machining Compatibility:It allows milling, drilling, boring, and tapping, meeting a variety of part machining needs.

Intelligent CNC Control System:Automatic path planning, machining optimization, and continuous multi-program machining capabilities improve production efficiency. The intuitive interface allows technicians to quickly learn how to use the machine.

Safe and Environmentally Friendly Design:Safety guards protect the operator, and the efficient chip ejection system keeps the work environment clean.