PRODUCT

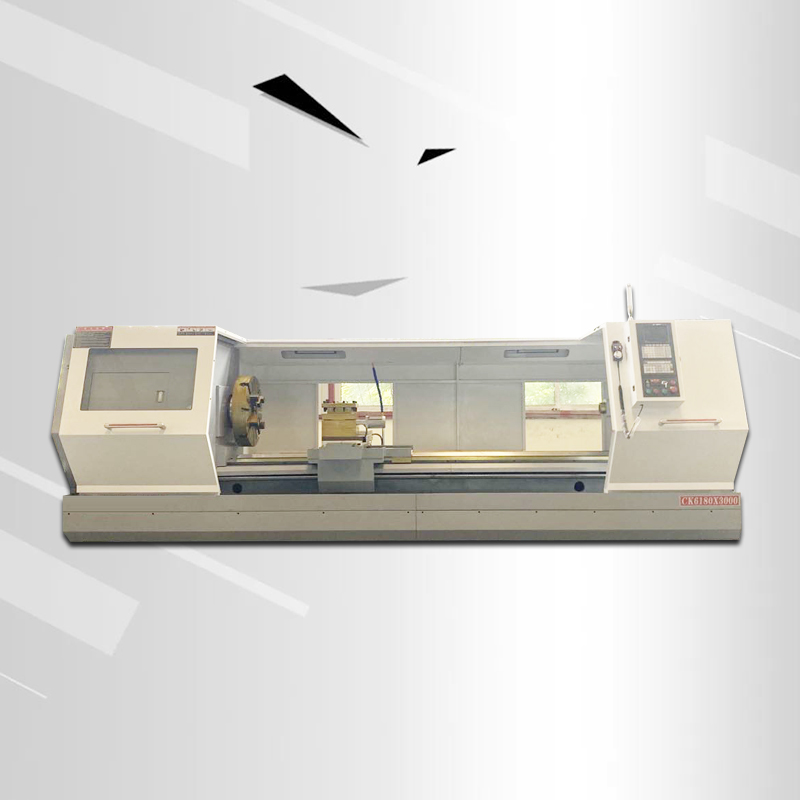

CNC lathe ALCK6180X3000 for sale at a low price

Recently, ALLES CNC successfully delivered an ALCK6180X3000 CNC lathe. With its outstanding performance, reliable structural design, and wide range of applications, this model has once again gained high recognition from customers.

Recently, ALLES CNC successfully delivered an ALCK6180X3000 CNC lathe. With its outstanding performance, reliable structural design, and wide range of applications, this model has once again gained high recognition from customers.

1.Key Features:

Large machining capacity: Maximum turning diameter up to 800mm and processing length 3000mm, suitable for long shafts, discs, and large-diameter parts.

High-rigidity bed: Made of high-strength cast iron with quenched guideways, ensuring excellent stability and vibration resistance.

Powerful spindle system: Large bore spindle with high-torque motor for heavy-duty cutting as well as high-speed finishing.

Stable CNC system: User-friendly, multifunctional system to improve productivity.

2.Main Advantages:

Strong stability with widened and reinforced bed design.

Wide machining range for both small and large batch production.

Higher efficiency with CNC automation.

Flexible configuration with optional chip conveyor, hydraulic chuck, and protective covers.

3.Application Industries:

Energy equipment (wind power shafts, oil drilling tools)

Metallurgical machinery (rolls, steel tube components)

Transportation (railway parts, ship propeller shafts)

Heavy machinery (construction and mining equipment parts)

4.Conclusion:

The ALCK6180X3000 CNC lathe, with its large capacity, high rigidity, and strong power, not only improves customer productivity but also demonstrates strong competitiveness in large workpiece machining. ALLES CNC will continue to provide global customers with high-quality, high-performance CNC solutions.

Product Specifications:

| Project | Content | Unit | CK6180*3000 |

| Processing range | Maximum turning diameter of bed | mm | Φ800 |

| Maximum turning diameter on skateboard | mm | Φ450 | |

| Maximum processing length | mm | 3000 | |

| Maximum machining diameter | mm | Φ800 | |

| Maximum bar diameter | mm | Φ450 | |

| Spindle | Chuck | / | 400 three claws/630 four claws (optional) |

| Spindle hole diameter | mm | Φ105 | |

| Taper of spindle bore | / | 1:20 | |

| Feed | X/Z axis travel | mm | 420/3000 |

| X/Z axis screw diameter × pitch | mm | φ3208/φ5010 | |

| X/Z fast moving speed | m/min | 4/6 | |

| Tool holder | Tool holder form | / | Electric vertical |

| Number of stations | / | 4 | |

| Tool specifications: turning/boring | mm | 32/40 | |

| Motor | Spindle motor power | Kw | 11 |

| Spindle motor torque | NM | 48 | |

| X/Z motor power | Kw | 1.5/2.3 | |

| X/Z motor torque | NM | 10/15 | |

| Cooling pump motor power | W | 125 | |

| Other | Machine weight | kg | 6200 |

| Machine size length×width×height | mm | 5400/1900/2000 |