PRODUCT

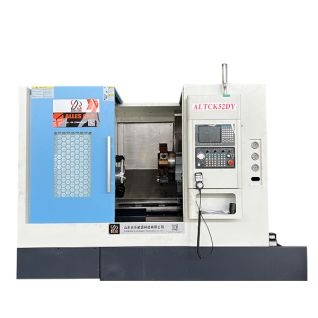

Flat bed CNC lathe ALCK6160

The ALCK6160 CNC lathe is a large-scale, high-performance precision CNC machine tool. It features a high-rigidity, integrally cast bed structure and undergoes secondary aging treatment, ensuring it remains stable during long-term use. This machine boasts powerful cutting capabilities and stable machining accuracy, making it suitable for both efficient batch processing of medium- and large-sized parts and precision single-piece production.

1. Product Overview

The ALCK6160 CNC lathe is a large-scale, high-performance precision CNC machine tool. It features a one-piece, high-rigidity cast bed structure with a secondary aging treatment to prevent deformation during long-term use. This machine offers strong cutting capabilities and stable machining accuracy, making it suitable for both efficient batch processing of medium- and large-sized parts and precision single-piece production.

2. Key Features

High-rigidity Structure: The bed is constructed of a single piece of high-quality cast iron, with wide guideways for high load capacity.

High-precision Spindle: Equipped with high-precision bearings, the spindle operates smoothly and offers excellent cutting stability.

High Cutting Capacity: Capable of high-volume machining, it is suitable for materials such as steel, cast iron, and non-ferrous metals.

Flexible Tailstock: The tailstock is movable and equipped with a center, facilitating the machining of long shaft parts.

Multiple System Options: Supports a variety of CNC systems, including Guangshu, KND, Siemens, and Fanuc, to meet diverse customer needs.

High Automation: Optional automatic chip conveyors, protective covers, and hydraulic chucks enhance production efficiency and safety.

3. Main Functions

External diameter, end face, and internal hole machining

Thread cutting (metric, imperial, module, pitch)

Circular, spherical, and complex curved surface machining

Support machining for long shaft parts

Automatic cycle machining of batch parts

4. Application Industries

Machinery manufacturing: Machining of various mechanical parts

Petrochemical industry: Flanges, pipe fittings, and large-diameter shafts

Shipbuilding: Propeller shafts, drive shafts, and rudder shafts

Metallurgical equipment: Roller shafts, couplings, and large-diameter sleeves

Mining machinery: Drill pipes, drive shafts, and bushings

Energy equipment: Wind turbine shafts and generator rotor components

5.Product Specifications:

| Item | Unit | CK6160x2000 |

| Max swing over bed | mm | Φ600 |

| Maximum turning diameter of carriage | mm | Φ310 |

| Maximum turning diameter | mm | Φ600 |

| Maximum turning length | mm | 2000 |

| X/Z axis maximum stroke | mm | 300/2000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Spindle series | / | stepless |

| Spindle speed limit | rpm | 150-1600 |

| Main motor power (frequency conversion) | kW | 7.5 |

| Frequency converter | kW | 7.5 |

| X/Z axis | N.m | 5/7.5 |

| X/Z axis rapid traverse speed | m/min | 6/8 |

| Tool holder type | / | 4-station tool holder |

| Tool bar size | mm | 25*25 |

| Repeated positioning accuracy of tool post | mm | ≤0.004 |

| Diameter of tailstock sleeve | mm | Φ75 |

| Tailstock sleeve stroke | mm | 200 |

| Machine size (length×width×height) | mm | 4400*1700*1800 |

| Electricity demand (power/current) | kW/A | 15kW/20A |