PRODUCT

Metal Turning CNC Lathe Machine CK6140 Horizontal Flat Bed Lathe

Maximum turning diameter of bed: 400mm

Maximum turning diameter on the tool post: 220mm

Center distance: 1000mm

The ALHAAS CNC CK6140/1000 lathe is designed for internal and external turning of parts with a diameter of up to 400 mm and a length of up to 1000 mm, as well as for drilling, reaming or threading.

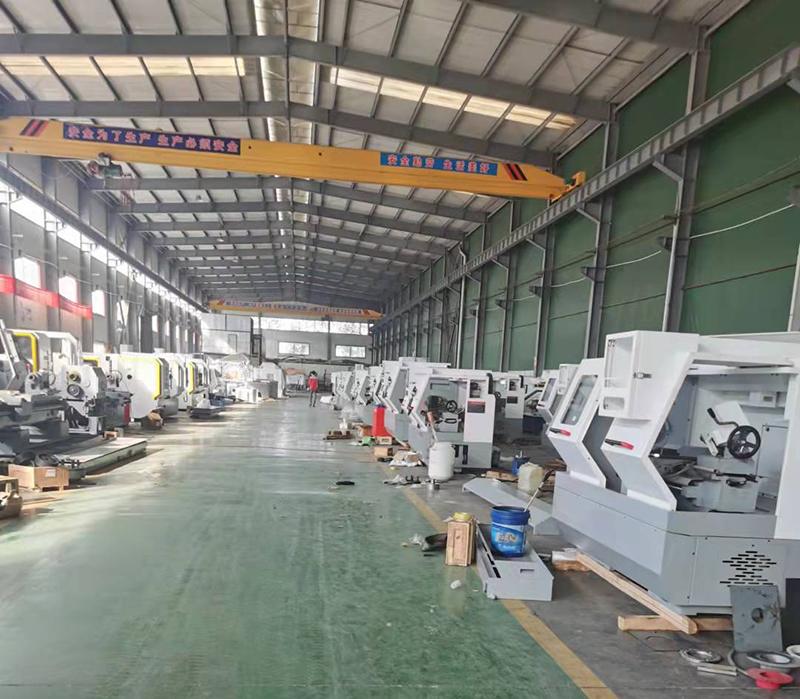

The CK6140x750 CNC lathe is a universal programmable metalworking machine for workshops and industrial plants, which has high performance to make it the optimal equipment for precise and automatic turning operations.

The CK6140x750 flat bed CNC metal turning machine is made of quality materials that give the structure a solid look. All major components such as bed, headstock, caliper, etc. are made by casting. Precision ball screws and precision bearings ensure accurate positioning and the ability to cut consistently even under maximum loads.

Product Specifications:

| Model | CK6140x1000 | |

| Processing capacity | Maximum turning diameter of bed | 400mm |

| Maximum turning diameter on the tool post | 220mm | |

| Center distance | 1000mm | |

| Rail width | 360mm | |

| X stroke | 250mm | |

| Z stroke | 900mm | |

| Headstock | Spindle hole diameter | 52mm |

| Max Spindle speed | 2200 | |

| Skateboard | Fast moving speed of carriage | X/Z:5/8m/min |

| Repeatability | Z:0.013mm X:0.012mm | |

| Number of tools | 4 | |

| Tailstock | Diameter of tailstock sleeve | 65mm |

| Taper of tailstock sleeve | MT4 | |

| Maximum stroke of tailstock sleeve | 120mm | |

Product Advantages:

The ALHAAS CNC machine model CK6140 is designed for high-speed, high-precision, semi-finishing and finishing machining of various types of shafts, discs, for boring holes, internal curved surfaces of a conical shape, threads, arcs, reamers. Suitable for high-speed cutting of ferrous and non-ferrous metals and machining of rotating parts. Provides high efficiency, large volumes and high processing accuracy. Designed and engineered using advanced foreign technologies. The design and controls are designed with ergonomics in mind: it is comfortable and easy to operate.

A series of CNC lathes of the CK series is used in all branches of the machine-building industry, as well as in the aerospace industry and instrument making.