PRODUCTO

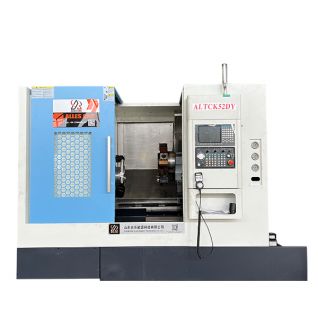

High Precision CNC Lathe ALCK0640 for Metal Processing

In today's rapidly developing manufacturing industry, companies are placing increasingly high demands on machine tools: they must ensure precision and efficiency while also meeting flexible processing needs. The ALCK0640 CNC lathe, a compact, high-performance machine tool, with its stable structural design, excellent machining performance, and wide application compatibility, has become a vital piece of equipment for modern manufacturers looking to improve productivity and product quality.

In today's rapidly developing manufacturing industry, companies are placing increasingly high demands on machine tools: they must ensure precision and efficiency while also meeting flexible processing needs. The ALCK0640 CNC lathe, a compact, high-performance machine tool, with its stable structural design, excellent machining performance, and wide application compatibility, has become a vital piece of equipment for modern manufacturers looking to improve productivity and product quality.

I. Key Features of the ALCK0640

Compact and Reasonable Design: The ALCK0640 features a compact bed structure, a small footprint, and a compact layout, making it ideal for factories and workshops with limited space. Its high-rigidity bed ensures stability during extended operation.

High-Precision Machining: The machine's spindle is precision-manufactured and balanced, and coupled with an advanced CNC system, it achieves high-precision turning. For machining small and complex parts, the ALCK0640 offers exceptional stability and repeatability.

Easy-to-Use Human-Machine Interface: The machine is equipped with a CNC system with a clear and user-friendly interface and supports programmed machining, significantly reducing operator workload and the risk of operational errors. Excellent chip evacuation and cooling design: In continuous batch machining, chip evacuation directly impacts machining efficiency. The ALCK0640 features an optimized chip evacuation channel and a cooling system to ensure surface quality and extend tool life.

Flexible process adaptability: Whether single-piece trial production, small-batch production, or batch machining, the ALCK0640 can easily handle it. It supports a variety of machining processes, including external cylindrical, internal hole, threading, and end-face machining.

II. Advantages of the ALCK0640

Outstanding cost-effectiveness: Compared to large CNC lathes, the ALCK0640 is more competitively priced while maintaining high precision and stability, making it a suitable investment for small and medium-sized enterprises.

Highly efficient production: Through CNC program control, the machine can complete multiple processes in a single clamping, reducing the time required for multiple workpiece handling and positioning, significantly improving production efficiency.

Easy maintenance: Designed with maintenance in mind, the ALCK0640 boasts a simple structure and easily replaceable and repairable parts, reducing maintenance costs and downtime. Energy-saving and Environmentally Friendly: The machine tool's power system has been optimized to ensure high performance while reducing energy consumption, in line with the development trend of green manufacturing.

Stable and Durable: The machine tool's core components are made of high-quality materials and strictly controlled machining precision, ensuring a long lifespan and stable operation.

III. Application Industries

The ALCK0640 CNC lathe, with its compactness, flexibility, high precision, and high efficiency, is widely used in various industries:

Automotive Industry: Suitable for precision machining of automotive parts such as shafts, sleeves, and threaded components, ensuring part consistency and interchangeability.

Aerospace Industry: In the machining of small structural parts and connectors, the ALCK0640 delivers high precision and stability, meeting the stringent quality requirements of the aerospace industry.

Mechanical Manufacturing Industry: The ALCK0640 is capable of turning a variety of small mechanical parts, such as gears, couplings, and bearing rings.

Electronics and Mold Industry: In the machining of electronic components and precision mold parts, the ALCK0640 is widely recognized for its high precision and excellent finish. Education and scientific research: Due to its small size and easy operation, the ALCK0640 is also commonly used in teaching and experiments in vocational schools and scientific research institutions to help students master CNC technology.

مواصفات المنتج:

| بند | الوحدة | CK0640 |

| أقصى قطر دوران للسرير | مم | Φ250 |

| أقصى قطر دوران للمنصة النقالة | مم | Φ80 |

| المغزل من خلال قطر الفتحة | مم | Φ48 |

| من خلال قطر فتحة أنبوب السحب | مم | 37 |

| أقصى سرعة للمغزل | rpm | 220 |

| قوة محرك المغزل | كو | 3 |

| أقصى مسافة لمحور X | مم | 200 |

| حركة المحور Z | مم | 220 |

| معدل التغذية السريع للمحور X | م / دقيقة | 6 |

| معدل التغذية السريع للمحور Z | م / دقيقة | 8 |

| نظام التحكم | / | GSK980TB3 |

| الأبعاد (الطول × العرض × الارتفاع) | ملم | 1640 × 1200 × 1650 |