PRODUCT

High Precision Slant Bed CNC Lathe ALTCK50 for Metal Turning

As modern manufacturing continues to pursue high precision, high efficiency, and high stability, CNC lathes have become core equipment for enhancing corporate competitiveness. The ALTCK50 CNC lathe, a high-performance model, is becoming an ideal choice for industries such as automotive, aviation, mold and die manufacturing, thanks to its advanced structural design, excellent machining performance, and wide range of applications. This article will comprehensively explain the value of the ALTCK50 from three perspectives: features, advantages, and application industries.

As modern manufacturing continues to pursue high precision, high efficiency, and high stability, CNC lathes have become core equipment for enhancing corporate competitiveness. The ALTCK50 CNC lathe, a high-performance model, is becoming an ideal choice for industries such as automotive, aviation, mold and die manufacturing, thanks to its advanced structural design, excellent machining performance, and wide range of applications. This article will comprehensively explain the value of the ALTCK50 from three perspectives: features, advantages, and application industries.

I. Main Features of the ALTCK50

High-rigidity slanted bed structure: The ALTCK50 utilizes a slanted bed design, which provides smoother chip evacuation and greater overall rigidity than traditional flat-bed structures. During machining, cutting forces are better dispersed, effectively reducing vibration and improving machining accuracy and tool life.

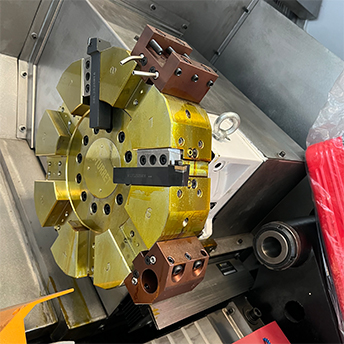

High-precision spindle system: The spindle is the core component of a lathe. The ALTCK50 is equipped with a high-precision spindle unit that operates smoothly, supports high-speed cutting, and delivers powerful torque output, making it suitable for both precision part machining and heavy cutting tasks. Large Travel and Flexible Configuration: The ALTCK50's rationally designed X and Z-axis travels meet the machining requirements of most parts. The machine can be equipped with optional tailstocks, automatic feeders, and powered turrets to meet customer needs, enabling diverse machining solutions.

Efficient CNC System: The machine is equipped with an advanced CNC system featuring a user-friendly interface, flexible programming, and features such as power-off protection, automatic lubrication, and alarm diagnostics, significantly enhancing its ease of operation and safety.

Reliable Protection: The ALTCK50 features a fully enclosed protective cover to prevent chip and coolant splashing, improving the operating environment and effectively extending the machine's service life.

II. Advantages of the ALTCK50

High-Efficiency Production Capacity: The ALTCK50 utilizes a slanted bed structure and a high-efficiency turret system, enabling fast tool changes and short cycle times, making it ideal for medium- and large-volume part production.

Precision and Stability: The machine's design fully considers the effects of thermal deformation and vibration, resulting in a rigid structure and high positioning accuracy. Whether performing continuous machining or turning complex curved surfaces, it maintains consistent precision. Cost Savings and Enhanced Competitiveness: By combining high efficiency and precision, the ALTCK50 can help companies shorten processing cycles, reduce scrap rates, and minimize tool wear, thereby effectively lowering production costs.

Intelligent Integration with Automation: The ALTCK50 supports integration with automatic loading and unloading systems, robots, and flexible production lines, enabling unmanned or reduced-management production. This automation upgrade provides a solid foundation for companies moving toward intelligent manufacturing.

Adaptability: The ALTCK50 is highly adaptable, accommodating both small-batch, high-variety production and large-volume continuous production. It is suitable for both precision parts manufacturing and general mechanical parts processing.

III. Application Industries

Automotive Manufacturing: In the automotive industry, the ALTCK50 is commonly used for machining engine components, transmission parts, steering system parts, and other components. These parts require extremely high precision and consistency, and the ALTCK50's stable machining capabilities ensure part quality and improve production efficiency.

Aerospace: Aerospace parts often feature complex structures and high-hardness materials. With its highly rigid structure and precision spindle, the ALTCK50 is capable of machining materials such as titanium alloys and high-temperature alloys, meeting the industry's stringent requirements for high precision and reliability.

Mold Manufacturing: The mold industry demands extremely high machining accuracy. The ALTCK50 can achieve the machining of complex curved surfaces and high-finish surfaces, shortening mold manufacturing cycles and improving mold quality.

Machinery Manufacturing: The ALTCK50 is widely used in parts machining for industries such as construction machinery, agricultural machinery, and energy equipment. It is particularly suitable for the efficient turning of large shafts, discs, and sleeves.

Hardware and Precision Parts: The ALTCK50 also has broad application in industries such as hardware tools and precision instruments. Its high efficiency and stable machining capabilities enable mass production of precision parts, ensuring dimensional consistency and surface finish.

IV. Summary

The ALTCK50 CNC lathe, with its highly rigid slanted bed structure, high-precision spindle system, and advanced CNC functions, perfectly combines high efficiency and high precision. Across various application industries, from automotive and aerospace to molds and mechanical equipment, the ALTCK50 demonstrates its powerful processing capabilities.

As manufacturing becomes increasingly intelligent and automated, the ALTCK50 is more than just a machine tool; it is a powerful tool for improving productivity, reducing costs, and enhancing market competitiveness. For companies striving for high quality and efficiency, the ALTCK50 is undoubtedly an ideal and reliable machine.

|

Item |

Unit |

Parameter |

|

Maximum slewing diameter on bed inner protection |

mm |

Φ560 |

|

Turning diameter |

mm |

Φ500 |

|

Turning length |

mm |

500 |

|

Spindle end type and code |

|

A2-5 |

|

Maximum passing bar diameter |

mm |

40 |

|

Spindle speed range |

rpm |

100-3000 |

|

Spindle power |

kw |

7.5 |

|

X-axis travel |

mm |

280 |

|

Z axis travel |

mm |

550 |

|

Tailstock rail model |

mm |

35 rollers/35 balls(Four sliders) |

|

Top model |

|

Morse No. 5 cone |

|

Spindle center to ground |

mm |

1000 |

|

Machine frame dimensions (length * width) |

mm |

2250*1005 |

|

Machine frame weight |

kg |

2400 |