PRODUCT

Horizontal CNC lathe ALCK6160X2000

In modern manufacturing, the machining of large shafts and disc-type parts demands higher standards of precision, efficiency, and stability. The ALCK6160X2000 CNC lathe, with its robust structural design, powerful performance, and wide applicability, has become an optimal choice for medium- to large-sized workpiece machining.

In modern manufacturing, the machining of large shafts and disc-type parts demands higher standards of precision, efficiency, and stability. The ALCK6160X2000 CNC lathe, with its robust structural design, powerful performance, and wide applicability, has become an optimal choice for medium- to large-sized workpiece machining.

1. Key Advantages

High-Rigidity Bed:Made of high-strength cast iron with an integral casting structure. The wide guideways are quenched and hardened, providing excellent vibration resistance and long-term stability, ideal for heavy-duty cutting.

Extended Machining Capacity:Maximum machining length of 2000mm, especially suitable for long shaft components.

Large Diameter Capability

Maximum swing diameter of Φ600mm, meeting diverse requirements for medium- and large-sized parts.

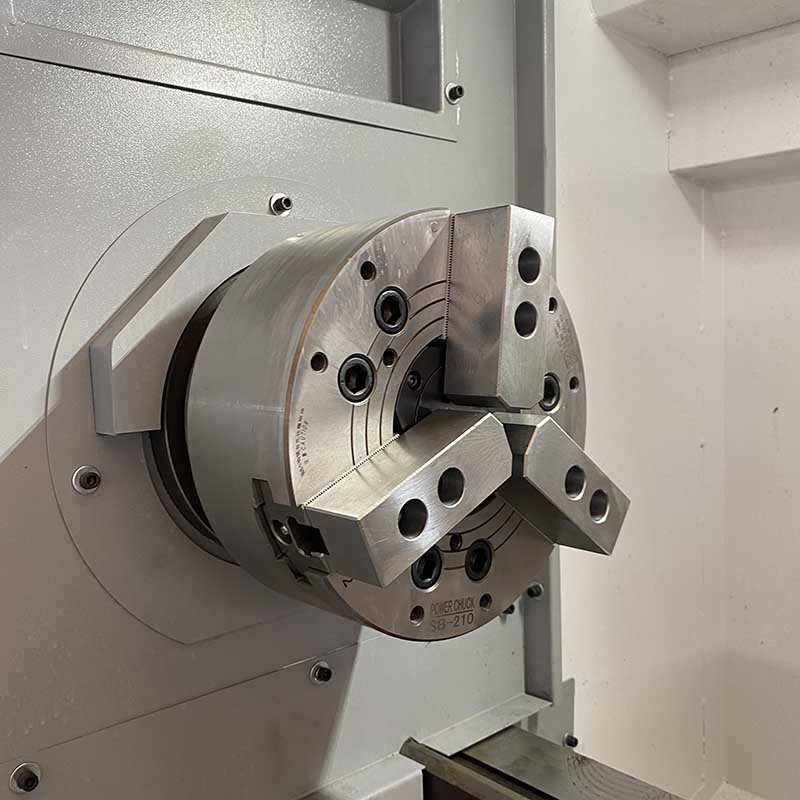

Powerful Spindle Drive:Equipped with a high-power, high-torque spindle motor, enabling efficient roughing and high-quality finishing with superior surface finish.

Accuracy and Stability:Spindle supported by high-precision bearings and controlled by an advanced CNC system, ensuring dimensional consistency and machining accuracy.

Ease of Operation:User-friendly CNC interface with flexible programming. Enhanced safety features and easy maintenance extend service life.

Multi-Functional MachiningCapable of conventional turning, threading, contouring, and complex profile machining. One machine serves multiple purposes, improving equipment utilization.

2. Application Industries

Construction Machinery: Shafts, connectors, load-bearing components.

Energy Equipment: Oil and gas pipe fittings, valves, large couplings, generator rotors, turbines.

Automotive Manufacturing: Medium- to large-sized parts for trucks and heavy-duty vehicles.

Shipbuilding: Large marine shafts, propeller accessories, structural connectors.

Metallurgy and Heavy Industry: Rolls, forgings, castings, and other heavy-duty metal components.

3. Summary

Long Travel & Large Diameter: Meets the demands of machining large and long-shaft workpieces.

High Rigidity & High Torque: Ensures stability for heavy cutting and continuous operation.

High Precision & Consistency: Guarantees quality in batch production.

Wide Industry Applications: Suitable for energy, shipbuilding, automotive, and construction machinery sectors.

The ALCK6160X2000 CNC lathe delivers outstanding overall performance and excellent cost-effectiveness, providing enterprises with efficient, stable, and precise solutions for medium- to large-sized part machining.

Product Specifications:

| Item | Unit | CK6160x2000 |

| Max swing over bed | mm | Φ600 |

| Maximum turning diameter of carriage | mm | Φ310 |

| Maximum turning diameter | mm | Φ600 |

| Maximum turning length | mm | 2000 |

| X/Z axis maximum stroke | mm | 300/2000 |

| X/Z axis minimum displacement unit | mm | 0.001 |

| Spindle hole diameter | mm | Φ82 |

| Spindle series | / | stepless |

| Spindle speed limit | rpm | 150-1600 |

| Main motor power (frequency conversion) | kW | 7.5 |

| Frequency converter | kW | 7.5 |

| X/Z axis | N.m | 5/7.5 |

| X/Z axis rapid traverse speed | m/min | 6/8 |

| Tool holder type | / | 4-station tool holder |

| Tool bar size | mm | 25*25 |

| Repeated positioning accuracy of tool post | mm | ≤0.004 |

| Diameter of tailstock sleeve | mm | Φ75 |

| Tailstock sleeve stroke | mm | 200 |

| Machine size (length×width×height) | mm | 4400*1700*1800 |

| Electricity demand (power/current) | kW/A | 15kW/20A |