PRODUCT

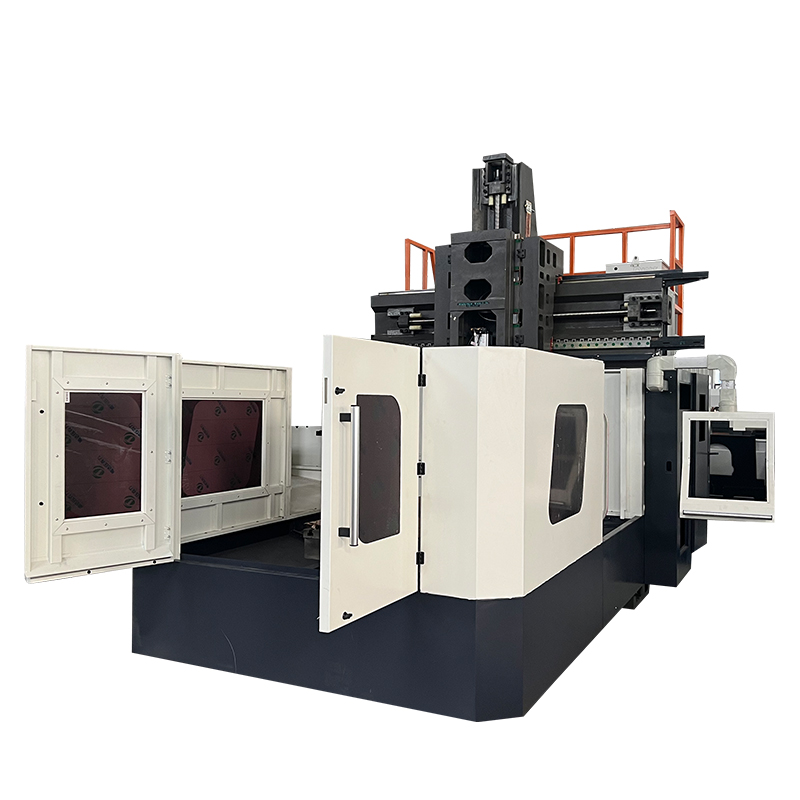

Gantry milling machine ALGMC1012

The ALGMC1012 is a high-performance fixed-beam CNC gantry milling machine designed for high-precision machining of medium- and large-sized metal parts. It boasts powerful cutting capabilities, stable structural rigidity, and a flexible machining range, making it widely used in industries such as molds, automotive, energy, and construction machinery.

The ALGMC1012 is a high-performance fixed-beam CNC gantry milling machine designed for high-precision machining of medium- and large-sized metal parts. It boasts powerful cutting capabilities, stable structural rigidity, and a flexible machining range, making it widely used in industries such as molds, automotive, energy, and construction machinery.

I. Main Features:

1. Fixed-beam gantry structure

The crossbeam is fixed, and the worktable is movable, resulting in a stable structure that facilitates high-precision machining.

The entire structure is constructed of resin-bonded sand cast iron, offering strong shock resistance and long-term deformation resistance.

2. Large machining stroke

The X/Y/Z axis travel is 1000 × 1200 × 450 mm (larger options available).

It is suitable for complex machining operations such as milling, drilling, and tapping on medium- and large-sized workpieces.

3. High-rigidity guideway system

Rectangular guideways or roller linear guideways (optional) are used to ensure load capacity and dynamic response.

High-quality lead screws on all three axes are directly connected to servo motors for precise positioning and fast response. 4. Powerful Spindle System

Equipped with a high-power spindle (such as the optional BT40/BT50), it supports powerful cutting.

An optional high-speed electric spindle meets the high finish requirements of mold products.

5. Intelligent CNC System

Equipped with CNC systems from brands such as Guangshu, Huazhong, Mitsubishi, and Siemens, it is easy to operate, stable, and reliable.

Supports multiple processing modes and G-code compatibility.

6. Safety and Maintenance

The fully enclosed sheet metal design provides excellent protection.

The user-friendly interface facilitates daily maintenance and repair.

II. Application Industries:

1. Mold Manufacturing: Injection molds, die-casting molds, and stamping molds.

2. Automotive: Engine housing and chassis component processing.

3. Machinery: Finishing of large structural parts and basic components.

4. Railway & Energy: Processing of aluminum alloy components and stainless steel parts. 5. Construction Machinery: such as brackets, boxes, connectors and other parts.

3.Product Specifications:

| Item | Unit | ALGMC1012 |

| Worktable | Worktable load (KG) | 2000 |

| Worktable size (mm) | 1000*1200 | |

| T-slot width | 18mm | |

| Dimensions | L*W*H(m)(About) | 3.4*2.3*2.6~2.9(Highest) |

| X.Y.Z Axis | Travel (mm) | 1000*1200*450 |

| X.Y axis fast moving speed(no load)( mm/min) | 10000 | |

| Z axis fast moving speed(mm/min) | 7000 | |

| Fastest processing speed(mm/min) | 6000 | |

| Positioning accuracy(mm) | +-0.01/300 | |

| Re-positioning accuracy(mm) | +-0.01 |