Company News

The LVMC1370 vertical machining center has completed its inspection and is officially shipped to Russia.

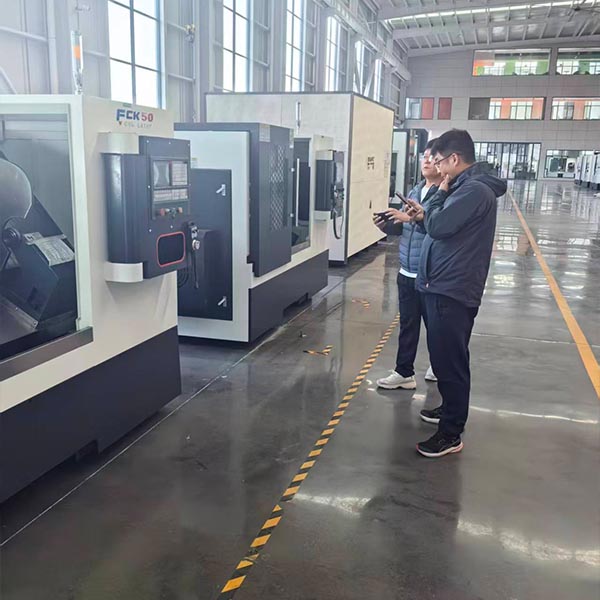

1. Successful Customer Acceptance Inspection

Recently, a customer from Russia completed the on-site acceptance inspection of the ALVMC1370 vertical machining center at the ALLES CNC factory.

With the technical engineer present throughout, the customer thoroughly inspected the machine tool's assembly accuracy, three-axis movement smoothness, spindle runout, system response speed, and overall machining stability.

After multiple tests, the equipment fully met the customer's technical requirements, receiving unanimous praise, and the acceptance inspection was successfully completed.

2. Equipment Performance and Technical Highlights

The ALVMC1370 is ALLES CNC's latest high-precision vertical machining center, boasting the following significant advantages:

High Rigidity Structure: Utilizing a heavy-duty cast iron bed and high-strength column design, it ensures stability even under high-speed cutting.

High-Precision Spindle: The spindle speed can reach 8000 rpm, coupled with precision imported bearings, achieving low noise and high stability.

Three-Axis Ball Screw Drive: High-precision ball screws combined with Japanese NSK bearings effectively improve positioning accuracy and repeatability.

Intelligent CNC System: Optional FANUC, Siemens, or GSK systems are available, offering a user-friendly interface and flexible operation.

Automatic Lubrication and Cooling System: Ensures long-term reliable operation and extends the service life of critical components.

3. Rigorous Quality Inspection and Packaging for Shipment

After passing the initial inspection, the ALLES CNC technical team immediately conducted final debugging and protective measures:

A comprehensive anti-rust coating was applied to the guide rails and lead screws;

All control cabinets and electrical components were secured and reinforced with shock-absorbing padding;

International standard moisture-proof wooden crates were used for packaging, with anti-tilt, anti-vibration, and waterproof markings affixed to the exterior;

The logistics department strictly followed export standard procedures to complete the packing and reinforcement, ensuring the equipment remained safe and undamaged during long-distance sea transport.

4. Service Guarantee and Technical Support

To enable customers to quickly begin production, ALLES CNC will provide the following services to Russian customers:

Remote video guidance for installation and commissioning;

Bilingual (Chinese and Russian) operation training materials;

Long-term spare parts supply and technical support.

The company's after-sales team will track the logistics and delivery status throughout the process to ensure smooth delivery and commissioning of the equipment.

5. Deepening the Russian Market and Continuously Expanding International Cooperation

Russia is one of ALLES CNC's important cooperative markets in Europe.

In recent years, the company has exported various models of CNC lathes, vertical machining centers, and gantry milling machines to Russian customers on multiple occasions. Thanks to their stable quality and high cost-effectiveness, they have earned the long-term trust and a good reputation among local customers.

This shipment of the ALVMC1370 once again demonstrates ALLES CNC's strength and reputation in the international high-end machine tool manufacturing field.